Product Description

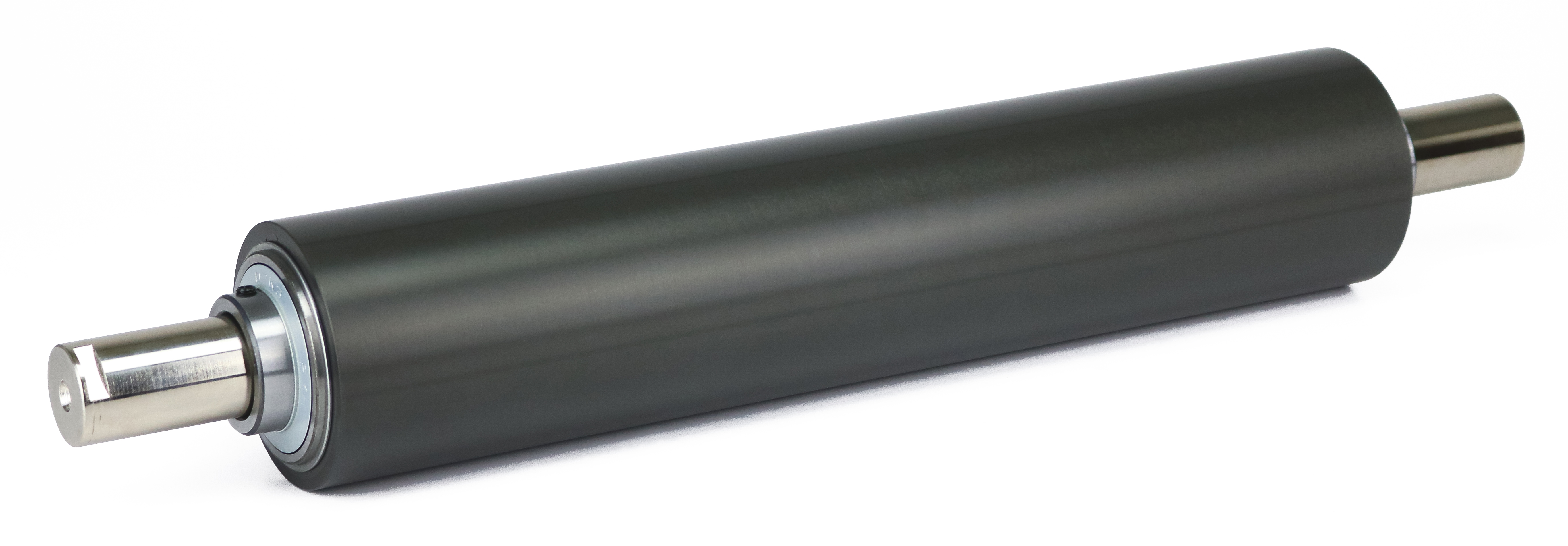

38mm to 216mm Diameter Customizable PVC Steel Rubber Idler Roller for Gravity Conveyor

Product Introduction

The Idler roller is often used on belt conveyor and conveying line, driven by motor or motor roller to reach the purpose of goods conveying. The idler roller could be customized based on your need in material, length, surface treating, etc.

Product Parameters

There are many different size rollers and the length, material, drive mode could be adjusted based on the customer’s specific requirements. So the listed price is only for your reference, please share us your detailed requirements then we can confirm the price.

Followed is the technical data of the A10 series idler roller for your reference:

Company Profile

ZheJiang Winroller Technology Co., Ltd is a global manufacturer of advanced transmission components, focusing on the development and production of micro and small electric conveyor roller.

With over 10 years in this field, we have achieved over 20 patents and enjoyed high popularity among the customers.

Exhibition

Certifications

We have received many patent certifications and CE, ISO certifcate. Followed are the pictures for your reference:

FAQ

Q: Are you trading company?

A: No, we are manufacturer with factory, with over 10 years of production experiences.

Q:How to select a suitable roller?

A:lf you have roller picture and diagram, it would be the best. Or you can tell us the requirements like the load weight, speed, diameter, work voltage, working state, etc.

Q: Do you have a customized service?

A: Yes, we can customize per your request for the voltage, speed, torque, etc.

Q: Do you have an individual design service for rollers ?

A: Yes, we would like to design rollers individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your advantage?

A: We have strong ability of research and development, all the motors and reducers and controllers are self-developed and manufactured. Till now, we have received over 20 patents.

If there is any interest, welcome to contact me.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Roller Length: | Depends |

|---|---|

| Application: | Conveying Use |

| Type: | Idler Roller |

| Material: | Carbon Steel/Galvanized/SS304/Customized |

| Product Name: | 38mm to 216mm Diameter Customizable PVC Steel Rubb |

| Transport Package: | Wooden Cases |

| Samples: |

US$ 300/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do idler rollers contribute to the adaptability and versatility of conveyor systems in various settings?

Idler rollers play a crucial role in enhancing the adaptability and versatility of conveyor systems in various settings. Here’s a detailed explanation of how idler rollers contribute to the adaptability and versatility:

- 1. Flexibility in Conveyor Design:

Idler rollers provide flexibility in conveyor design by offering different configurations and options. They can be easily integrated into various conveyor layouts, including straight sections, curves, inclines, and declines. Idler rollers come in different sizes, materials, and designs to accommodate specific application requirements. This flexibility allows conveyor systems to be customized and tailored to fit different spatial constraints and production needs, making them adaptable to different settings.

- 2. Handling a Wide Range of Materials:

Idler rollers are designed to handle a wide range of materials, from lightweight and delicate items to heavy and bulky loads. They can be constructed with different surface finishes, such as smooth, grooved, or impact-resistant, to suit specific material characteristics. The ability of idler rollers to handle diverse materials, including packages, containers, bulk materials, and more, makes conveyor systems adaptable to various industries such as manufacturing, logistics, mining, and agriculture.

- 3. Compatibility with Different Conveyor Belt Types:

Idler rollers are compatible with different types of conveyor belts, including fabric belts, modular belts, steel cord belts, and more. They provide support and guidance to the conveyor belt, ensuring proper tracking and alignment. The compatibility with various belt types allows conveyor systems to be adapted for specific application requirements, such as high-speed conveying, heavy-duty operations, or specialized material handling processes.

- 4. Easy Integration with Ancillary Equipment:

Idler rollers can be easily integrated with ancillary equipment and accessories to enhance the functionality and adaptability of conveyor systems. For example, side guide rollers can be added to ensure proper product orientation and prevent lateral movement. Impact idler rollers can be installed in areas where the conveyed material experiences impact or excessive loading. By incorporating such specialized idler rollers and accessories, conveyor systems can be adapted to handle specific product types, optimize material flow, and improve overall system performance.

- 5. Adjustable Configurations and Angles:

Idler rollers offer adjustable configurations and angles, allowing for easy customization and adaptability. Conveyor systems can be designed with adjustable idler frames, allowing the height and angle of the rollers to be modified to accommodate changes in product size, weight, or process requirements. This adjustability enables conveyor systems to adapt to evolving production needs and handle a variety of product dimensions, contributing to their versatility in different settings.

- 6. Modular and Expandable Designs:

Many idler roller systems are designed with modularity and expandability in mind. They consist of individual idler roller units that can be easily connected and disconnected, allowing for flexible system configurations and future expansions. Conveyor systems can be adapted and scaled up or down based on changing production demands, facility layouts, or operational requirements. This modularity and expandability make idler rollers an integral component in creating versatile and adaptable conveyor systems.

In summary, idler rollers contribute significantly to the adaptability and versatility of conveyor systems in various settings. Their flexibility in conveyor design, ability to handle diverse materials, compatibility with different belt types, easy integration with ancillary equipment, adjustable configurations and angles, and modular designs make them essential for creating conveyor systems that can be adapted to different industries, applications, and production needs.

How does the design of idler rollers contribute to efficient and smooth material movement?

The design of idler rollers plays a crucial role in facilitating efficient and smooth material movement in conveyor systems. Various design features are incorporated to optimize the performance and functionality of idler rollers. Here are some ways in which the design of idler rollers contributes to efficient and smooth material movement:

- Roller Diameter and Length:

The diameter and length of idler rollers are carefully determined based on the specific application and load requirements. Larger roller diameters distribute the load over a larger surface area, reducing the pressure on the belt and minimizing belt deformation. Longer idler rollers provide more support along the conveyor belt, ensuring better weight distribution and reducing the risk of sagging or belt misalignment. The appropriate selection of roller diameter and length helps maintain optimal belt tension and prevents material spillage, contributing to smooth material movement.

- Roller Material and Construction:

The choice of materials and construction of idler rollers are essential for their performance and durability. Idler rollers are commonly made from materials such as steel, rubber, or high-strength composites. The material selection depends on factors such as load capacity, environmental conditions, and the type of material being conveyed. For example, steel rollers provide excellent strength and durability for heavy-duty applications, while rubber-coated rollers offer enhanced grip and reduced noise levels. The construction of idler rollers incorporates features like precision bearings, shafts, and seals to ensure smooth rotation and minimize friction, contributing to efficient material movement.

- Roller Configuration:

The configuration of idler rollers is optimized to support the conveyor belt and facilitate smooth material movement. Troughing idler rollers, with their concave shape, help contain the material being conveyed and prevent spillage off the sides of the belt. Impact idler rollers are designed to absorb the impact of heavy or sharp-edged materials, protecting the belt and reducing material degradation. Return idler rollers support the return side of the belt and assist in belt tracking, ensuring proper tension and alignment. Training idler rollers can be adjusted to apply lateral forces and guide the belt back to the center of the conveyor frame, minimizing belt misalignment. The appropriate configuration of idler rollers ensures proper belt support, alignment, and tracking, contributing to efficient and smooth material movement.

- Roller Surface and Coatings:

The surface of idler rollers is designed to minimize friction and optimize material movement. Idler rollers may have smooth or textured surfaces depending on the specific application requirements. Smooth surfaces reduce friction between the roller and the belt, reducing power requirements and energy consumption. Textured surfaces, such as diamond or spiral patterns, enhance grip and prevent material slippage on steep inclines or in wet conditions. Additionally, idler rollers can be coated with materials like polyurethane or rubber to further reduce friction, enhance belt grip, and provide additional protection to the belt surface. The surface design and coatings of idler rollers contribute to efficient and smooth material movement by reducing belt slippage, minimizing wear, and improving overall conveyor system performance.

In summary, the design of idler rollers is carefully engineered to optimize their performance and contribute to efficient and smooth material movement. Factors such as roller diameter and length, material selection, roller configuration, and surface design all play a role in ensuring proper belt support, alignment, and reduced friction. By providing adequate support, minimizing belt deformation, and reducing frictional resistance, well-designed idler rollers contribute to the overall efficiency, reliability, and longevity of conveyor systems in facilitating the movement of materials.

editor by Dream 2024-05-17

China Professional Bacteria Free Trough Roller/Belt Conveyor Idlers, Conveyors, Conveyor Roller

Product Description

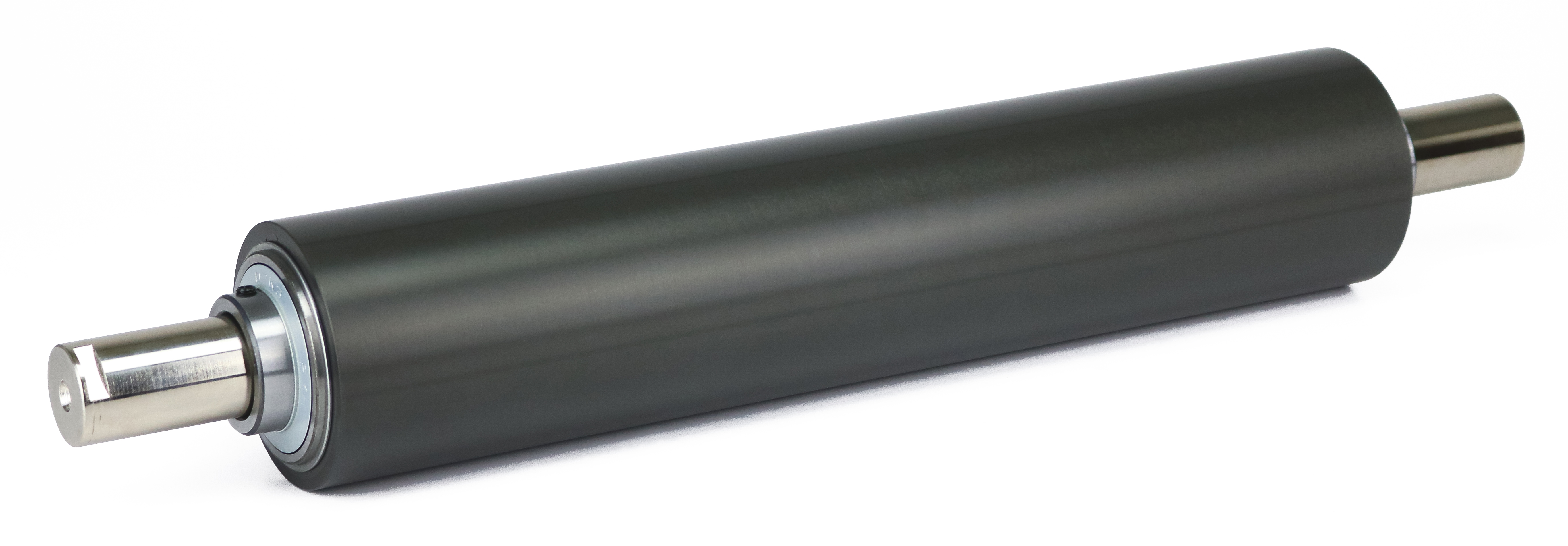

Bacteria Free Trough Roller/Belt Conveyor Idlers, Conveyors, Conveyor Roller

Roller , conveyor roller

we make different kinds of roller for conveyor system , delivery system , transport system etc. we also make according to customer’s design or drawing .

1. welding product dimension : from 0.1m—10m , steel sheet , steel sections , pipes , weight from 0.5kg to 5000kg

2. mateial from steel , stainless , aluminum etc , from steel sheet , sections , chanels , pipes , etc

3. welding process: cut material into shape , grind the burs if have , make welding jig or tooling for scaled wedling , point welding first , inspect dimension after point welding, welding all necessary areas reqeusted , welding stress relief after welding ( as buyer’s request) , make finish request , packing and shipping

4. finish treatment available : hot dipping galvanised , zinc plated , paint , powder coating , satin , mirror polish etc

productuion equipment list :

| available process material | carbon steel , stainless , aluminum, brass , copper , bronze , steel alloy ,Nylon ,plastic etc |

| finish treatment available | polish , zinc , hard anodizing , nickel plating , chrome plating , powder coating , phostate coating ,sanblasting |

| heat treatment available | annealing, quenching hardening, blacking,tempering ,nitriding etc |

process equipment list

| equipment | process part size | qty | model |

| gantry milling machine | 6000*2300*1600 | 1 | BX2571 |

| gantry milling machine | 3000*1200*800 | 1 | XQ2012 |

| CNC centre | 1000*600 | 1 | 1060 |

| CNC centre | 1300*700 | 1 | 1370 |

| CNC centre | 4300*2700 | 1 | 4370 |

| vertical milling machine | 1500 | 1 | X53T |

| gantry boring and milling | 1800*4000 | 1 | B**2018 |

| horizontal milling machine | 960*1200*1200 | 1 | TP *611B |

| horizontal lathe | dia300*3000 | 4 | CW6163E |

| saw machine | dia5—300 | 4 | |

| grinding machine | 1000*300 | 1 | M71304 |

| grinding macnine for outer dia | 1500*3200 | 1 | M1332B |

| gantry CNC centre | 4000*2700 | 1 | YR4571 |

| common lathe | dia20–1280,L 20–5000 | 6 | |

| common drilling machine | dia2–80 | 6 | |

| plasma cut machine | 4000*12000 | 1 | SXL-400 |

| arc welding machine | 2 | 500-2 | |

| co2 welding machine | 14 | 350 500 | |

| other common machine | common milling ,lathe , driling and milling machine etc | ||

Other products

Company Profile

HangZhou ConRingWon Industry & Trade Co., Ltd. Founded on November 25, 2016.Processing, manufacturing and marketing of mechanical equipment and spare parts (excluding special equipment), steel and plastic products, hardware products, welding sheet metal products, import and export of goods, technology import and export (except items prohibited by laws and administrative regulations.

Production factory

Product Packing & Delivery

Product quality certification

FAQ

Q1: Are you a factory or trading company?

A:We are a factory and have more years manufacture and sales experience.

Q2: What is your sample policy?

A:We can supply the sample if we have , but the customers have to pay the sample cost and the courier cost.If sample quantity is more than our regular one, we will extra collect sample cost.

Q3: Can you produce according to the samples?

A:Yes, we can produce by your samples or technical drawings. We can build the molds.

Q4: What’s your delivery time?

A:For regular products, we keep them in stock. The specific delivery time depends on the items and the quantity of your order,usually15-20 days

Q5:What is your terms of payment?

A:T/T 30% as deposit, and 70% before delivery.

Q6:Do you test all your goods before delivery?

A:Yes, we have 100% test before delivery.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Roller: | 5 |

|---|---|

| Transport Package: | Soft Film and Wood Box |

| Specification: | diameter 75–150mm |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What safety considerations should be taken into account when using idler rollers in industrial settings?

When using idler rollers in industrial settings, it is essential to prioritize safety and take specific considerations into account. Here’s a detailed explanation of the safety considerations that should be taken into account:

- 1. Guarding and Enclosure:

Idler rollers should be properly guarded and enclosed to prevent accidental contact with moving parts. Guards or barriers should be installed around the idler roller assemblies, ensuring that workers cannot reach or come into contact with the rotating rollers. This helps reduce the risk of entanglement, pinching, or other types of injuries caused by contact with the moving components.

- 2. Lockout/Tagout Procedures:

Lockout/tagout procedures should be implemented when performing maintenance, repairs, or adjustments on conveyor systems involving idler rollers. Lockout/tagout procedures ensure that the conveyor system is de-energized and isolated from power sources before any work is performed. This prevents unexpected startup or movement of the conveyor system, protecting workers from potential hazards associated with idler rollers and other conveyor components.

- 3. Training and Education:

Proper training and education should be provided to workers who operate or work around conveyor systems with idler rollers. Workers should be trained on the safe operation, maintenance procedures, and potential hazards associated with idler rollers. They should understand how to recognize and respond to emergency situations, such as belt jams, material spillage, or abnormal noises. Ongoing training programs can help promote a safety-conscious culture and prevent accidents in industrial settings.

- 4. Regular Inspection and Maintenance:

Regular inspection and maintenance of idler rollers are crucial for identifying and addressing any potential safety hazards. Routine inspections should be conducted to check for signs of wear, damage, or misalignment of the idler rollers. Any issues should be promptly addressed, and damaged or worn-out idler rollers should be replaced. Proper lubrication of bearings and other moving parts should also be part of the maintenance routine to ensure smooth and safe operation.

- 5. Ergonomics and Manual Handling:

Ergonomic considerations should be taken into account when designing workstations or tasks involving idler rollers. Proper lifting techniques and manual handling practices should be followed when moving or installing idler rollers to prevent strains or musculoskeletal injuries. Adequate lifting equipment or assistance should be provided for heavy or bulky idler rollers to minimize the risk of injuries associated with manual handling.

- 6. Hazard Signage and Communication:

Clear and visible hazard signage should be placed in areas where idler rollers are present to alert workers to potential risks. Safety information, warnings, and instructions should be communicated effectively to ensure that all personnel are aware of the hazards associated with idler rollers and understand the necessary safety precautions. This can be achieved through signage, safety training programs, safety meetings, and regular communication channels.

In summary, ensuring safety when using idler rollers in industrial settings requires proper guarding and enclosure, implementation of lockout/tagout procedures, adequate training and education, regular inspection and maintenance, consideration of ergonomics and manual handling practices, and effective hazard signage and communication. By adhering to these safety considerations, the risks associated with idler rollers can be minimized, creating a safer working environment in industrial settings.

How does the design of idler rollers contribute to efficient and smooth material movement?

The design of idler rollers plays a crucial role in facilitating efficient and smooth material movement in conveyor systems. Various design features are incorporated to optimize the performance and functionality of idler rollers. Here are some ways in which the design of idler rollers contributes to efficient and smooth material movement:

- Roller Diameter and Length:

The diameter and length of idler rollers are carefully determined based on the specific application and load requirements. Larger roller diameters distribute the load over a larger surface area, reducing the pressure on the belt and minimizing belt deformation. Longer idler rollers provide more support along the conveyor belt, ensuring better weight distribution and reducing the risk of sagging or belt misalignment. The appropriate selection of roller diameter and length helps maintain optimal belt tension and prevents material spillage, contributing to smooth material movement.

- Roller Material and Construction:

The choice of materials and construction of idler rollers are essential for their performance and durability. Idler rollers are commonly made from materials such as steel, rubber, or high-strength composites. The material selection depends on factors such as load capacity, environmental conditions, and the type of material being conveyed. For example, steel rollers provide excellent strength and durability for heavy-duty applications, while rubber-coated rollers offer enhanced grip and reduced noise levels. The construction of idler rollers incorporates features like precision bearings, shafts, and seals to ensure smooth rotation and minimize friction, contributing to efficient material movement.

- Roller Configuration:

The configuration of idler rollers is optimized to support the conveyor belt and facilitate smooth material movement. Troughing idler rollers, with their concave shape, help contain the material being conveyed and prevent spillage off the sides of the belt. Impact idler rollers are designed to absorb the impact of heavy or sharp-edged materials, protecting the belt and reducing material degradation. Return idler rollers support the return side of the belt and assist in belt tracking, ensuring proper tension and alignment. Training idler rollers can be adjusted to apply lateral forces and guide the belt back to the center of the conveyor frame, minimizing belt misalignment. The appropriate configuration of idler rollers ensures proper belt support, alignment, and tracking, contributing to efficient and smooth material movement.

- Roller Surface and Coatings:

The surface of idler rollers is designed to minimize friction and optimize material movement. Idler rollers may have smooth or textured surfaces depending on the specific application requirements. Smooth surfaces reduce friction between the roller and the belt, reducing power requirements and energy consumption. Textured surfaces, such as diamond or spiral patterns, enhance grip and prevent material slippage on steep inclines or in wet conditions. Additionally, idler rollers can be coated with materials like polyurethane or rubber to further reduce friction, enhance belt grip, and provide additional protection to the belt surface. The surface design and coatings of idler rollers contribute to efficient and smooth material movement by reducing belt slippage, minimizing wear, and improving overall conveyor system performance.

In summary, the design of idler rollers is carefully engineered to optimize their performance and contribute to efficient and smooth material movement. Factors such as roller diameter and length, material selection, roller configuration, and surface design all play a role in ensuring proper belt support, alignment, and reduced friction. By providing adequate support, minimizing belt deformation, and reducing frictional resistance, well-designed idler rollers contribute to the overall efficiency, reliability, and longevity of conveyor systems in facilitating the movement of materials.

editor by Dream 2024-05-17

China Hot selling Industrial Belt Conveyor Idler Rubber Impact Galvanized Roller

Product Description

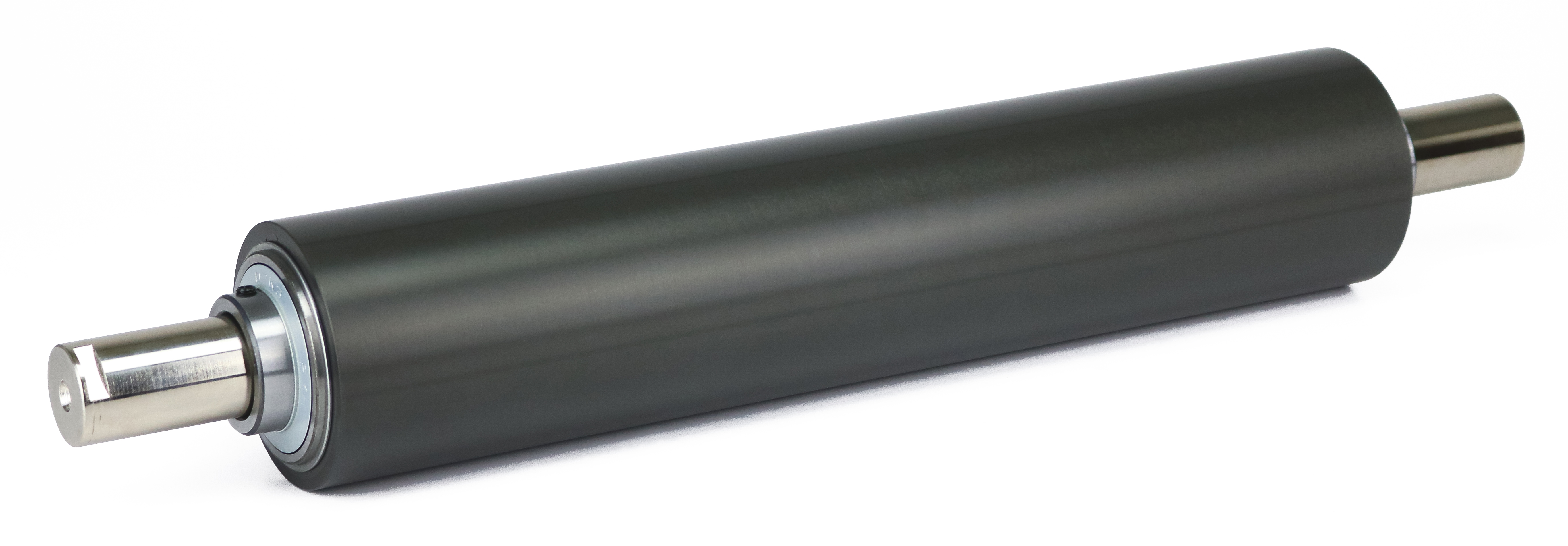

CONVEYOR ROLLERS,CONVEYOR IDLERS,CONVEYOR SPARE PARTS, CONVEYOR DRUMS PULLEYS

FOR BULK MATERIAL HANDLING PROJECTS

Advantages and Benefits:

1, CHINAMFG design for heavy duty roller.

2, Waterproof and dustproof design

3, Low indicated run out (T.I.R) , good balance, stable operation .

4, Low resistance for start and friction, high efficiency and energy saving.

5, The bearing house and tube are assembled and welded with a concentric automatic welding machine.

6, Cutting of steel tube and shaft is performed with digital auto equipment.

7, Fabrication of roller is effected by an auto device.

8, The conveyor rollers are manufactured accoding to CEMA,ASTM,DIN standard.

9, The conveyor roller is lubricated and free from maintenance.

Raw material and specifications are as below:

A:Shaft is made from cool drawn steel, cut and machined by automatic numerically controlled machines, the concentricity in 0.05mm.

B:The tube is made from ST37-2 DIN standard and machined by automatic numerically controlled machines.

C:Bearing are deep groove precision ball bearing with C3 internal clearance.

D:Bearing house are made from cold-forming and machinesd by automatic numerically controlled machines

E:The seals are triple labyrinth seals and made from nylon PA6 material.

F:The grease uses 2,3 grade long-lasting lithium grease.

| Technical Parameters | ||||

| Standard Diameter | Length scope ( mm) | Bearings Type (Min~Max) |

Idler’s Shell Wall Thickness | |

| mm | Inch | |||

| 63.5 | 2 1/2 | 150~3500 | 204 | 3.0mm~3.75mm |

| 76 | 3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 89 | 3 1/3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 102 | 4 | 150~3500 | 3.5mm~4.0mm | |

| 108 | 4 1/4 | 150~3500 | 3.5mm~4.0mm | |

| 114 | 4 1/2 | 150~3500 | 3.5mm~4.5mm | |

| 127 | 5 | 150~3500 | 3.5mm~4.5mm | |

| 133 | 5 1/4 | 150~3500 | 306 | 3.5mm~4.5mm |

| 140 | 5 1/2 | 150~3500 | 306 | 3.5mm~4.5mm |

| 152 | 6 | 150~3500 | 4.0mm~4.5mm | |

| 159 | 6 1/4 | 150~3500 | 4.0mm~4.5mm | |

| 165 | 6 1/2 | 150~3500 | 308 | 4.5mm~6.0mm |

| 177.8 | 7 | 150~3500 | 309 | 4.5mm~6.0mm |

| 190.7 | 7 1/2 | 150~3500 | 309 | 4.5mm~6.0mm |

| 194 | 7 5/8 | 150~3500 | 310 | 4.5mm~6.0mm |

| 219 | 8 5/8 | 150~3500 | 4.5mm~6.0mm | |

Typical applicatios:Mining—coal, iron ore,gold,Coal process plants,Coal fired power stations,Import/export terminals,Steel plants,Fertilizer plants,Cement plants,Gravel plants,Quarry.

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Carbon Steel |

|---|---|

| Surface Treatment: | Baking Paint |

| Motor Type: | Frequency Control Motor |

| Installation: | Horizontal |

| Size: | Customer-Made |

| Roller Length: | 190mm to 3500mm |

| Customization: |

Available

|

|

|---|

How do electronic or computer-controlled components integrate with idler rollers in modern applications?

Electronic or computer-controlled components play a significant role in modern material handling applications, and they can integrate with idler rollers to enhance functionality, monitoring, and control. Here’s a detailed explanation of how electronic or computer-controlled components integrate with idler rollers in modern applications:

- 1. Sensor Integration:

Electronic sensors can be integrated with idler rollers to gather real-time data about their performance and the surrounding environment. For example, proximity sensors can be used to detect the presence or position of materials on the conveyor belt. These sensors can provide feedback to the control system, enabling automatic adjustments in the material handling process, such as activating diverters or adjusting conveyor speed based on the material’s position.

- 2. Load Monitoring:

Load cells or weight sensors can be utilized in combination with idler rollers to measure the weight or load of materials being conveyed. This information can be transmitted to a computer-controlled system for real-time monitoring and control of the material handling process. Load monitoring can help optimize material flow, prevent overloading, and ensure efficient operation of the conveyor system.

- 3. Condition Monitoring:

Idler rollers can be equipped with electronic monitoring devices to assess their condition and detect any abnormalities or signs of wear. Vibration sensors, temperature sensors, or acoustic sensors can be integrated to monitor roller performance and detect potential issues such as bearing failure, misalignment, or excessive wear. This data can be analyzed in real-time or transmitted to a central control system for condition-based maintenance, allowing for proactive repair or replacement of idler rollers before failures occur.

- 4. Automated Control and Optimization:

Computer-controlled systems can integrate with idler rollers to automate and optimize material handling processes. By analyzing data from sensors and other sources, the control system can make real-time decisions and adjustments to optimize conveyor speed, belt tension, and idler roller positioning. This automation improves efficiency, reduces human intervention, and enhances overall system performance.

- 5. Communication and Connectivity:

Electronic or computer-controlled components in idler rollers can be equipped with communication capabilities to connect with other devices or systems in the material handling environment. This allows for seamless integration with supervisory control systems, data logging systems, or enterprise resource planning (ERP) systems. The idler rollers can send data, receive instructions, and participate in a networked ecosystem for centralized control, monitoring, and reporting.

- 6. Predictive Analytics and Maintenance:

By combining electronic sensors, data analysis, and computer-controlled components, modern applications can employ predictive analytics to anticipate idler roller failures or maintenance needs. Advanced algorithms can analyze historical data, sensor inputs, and operational parameters to predict the remaining useful life of idler rollers. This enables proactive maintenance planning, reducing downtime, and optimizing maintenance schedules for improved overall system availability.

In summary, electronic or computer-controlled components integrate with idler rollers in modern applications to enhance functionality, monitoring, and control. Sensor integration, load monitoring, condition monitoring, automated control, communication and connectivity, and predictive maintenance are some of the ways these components work together to optimize material handling processes, improve efficiency, and increase the reliability of idler roller systems.

What are idler rollers, and how do they function in conveyor systems?

Idler rollers, also known as conveyor idlers or simply idlers, are an essential component of conveyor systems. They play a crucial role in supporting and guiding the conveyor belt or other conveying surfaces, facilitating the efficient movement of materials. Idler rollers are typically cylindrical in shape and are positioned along the length of the conveyor system.

The primary function of idler rollers is to support and shape the conveyor belt. They provide a stable platform for the belt to rest on and help maintain its proper alignment and tension. Idler rollers are strategically placed at various intervals along the conveyor, creating a series of support points. These support points distribute the weight of the conveyed materials and minimize the sagging or deformation of the belt, ensuring smooth and consistent material movement.

Idler rollers also help to reduce friction between the belt and the supporting structure of the conveyor system. By allowing the belt to roll over them, they minimize the contact area and the associated frictional resistance. This reduces power requirements and energy consumption, contributing to the overall efficiency of the system.

Another important function of idler rollers is to guide the conveyor belt and prevent it from deviating from its intended path. They are designed with precise dimensions and smooth surfaces to ensure proper belt tracking. The alignment of idler rollers is critical for maintaining the belt’s centered position within the conveyor frame. Well-aligned idler rollers help prevent material spillage, belt misalignment, and potential damage to the system.

Idler rollers are available in various designs and configurations to suit different conveyor system applications. Some common types of idler rollers include:

- Troughing Idlers: These idlers have a concave shape and are used to support the conveyor belt on the carrying side. They help contain the material being conveyed, preventing it from spilling off the sides of the belt.

- Impact Idlers: Impact idlers are designed to absorb the impact of heavy or sharp-edged materials as they fall onto the conveyor belt. They are often positioned in the loading zone to protect the belt and other components from damage.

- Return Idlers: Return idlers support the return side of the conveyor belt and help maintain its tension. They are positioned beneath the belt to support its lower run and assist in belt tracking.

- Training Idlers: Training idlers are used to correct belt misalignment and ensure proper tracking. They are typically adjustable and can be positioned to apply lateral forces to the belt, guiding it back to the center of the conveyor frame.

In summary, idler rollers are integral components of conveyor systems. They provide support, shape, and guide the conveyor belt, ensuring smooth material movement and maintaining proper belt alignment. By minimizing friction and facilitating efficient belt tracking, idler rollers contribute to the overall performance, reliability, and efficiency of conveyor systems.

editor by Dream 2024-05-16

China Standard Belt Conveyor Trough Idler Roller Carrying Idlers Polyurethane Roller for Papermaking

Product Description

As the speed of the paper machine becomes faster and faster, more efficient dehydration of the press section is required. The application of polyurethane encapsulation with higher surface opening rate is appear! Advantages: the polyurethane surface is designed as a press roll with grooves and blind holes, which generates a large amount of water in the nip, greatly improves the dewatering capacity of the nip, and reduces the dependence on felt dewatering.

Our Advantages

Certifications

Packaging & Shipping

FAQ

FAQ

Q: Are you a manufacturer?

A: Yes, we can provide you with professional production and processing.

Q: How to install the machine?

A: We can help the installation by video, email, picture. For large projects, we can arrange for our workers to help you install in your country.

Q: How do you package the product?

A: Usually as export standard packing or as your request.

Q: What is your available shipping port?

A: HangZhou Port, ZheJiang Port and so on.

Q: Can it be customized?

A: Yes, according to the detailed drawings you provide /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Polyurethane Rubber |

|---|---|

| Usage: | Printing and Dyeing Roller, Papermaking Rubber Roller |

| Roller Surface Material: | Polyurethane Resins |

| Rubber Roller Core Structure: | Heavy Roller |

| Rubber Hardness: | Hard Rubber Roller |

| Configuration of Surface: | The Pattern Roller |

| Customization: |

Available

|

|

|---|

Are there innovations or advancements in idler roller technology that have emerged recently?

Yes, there have been several innovations and advancements in idler roller technology that have emerged recently. These advancements aim to improve the performance, reliability, and sustainability of idler rollers in material handling systems. Here’s a detailed explanation of some of the recent innovations in idler roller technology:

- 1. Self-Lubricating Idler Rollers:

One notable advancement is the development of self-lubricating idler rollers. Traditional idler rollers require regular lubrication to reduce friction and prevent premature wear. However, self-lubricating idler rollers incorporate innovative materials and lubrication mechanisms that eliminate the need for external lubrication. This reduces maintenance requirements, lowers operational costs, and improves overall system efficiency.

- 2. Composite and Lightweight Materials:

Advancements in material science have led to the use of composite and lightweight materials in idler roller construction. These materials offer high strength-to-weight ratios, improved wear resistance, and corrosion resistance. Composite idler rollers are not only durable but also contribute to energy savings by reducing the weight and inertia of the rotating components. The use of lightweight materials also reduces the load on conveyor systems and extends their service life.

- 3. Precision Bearing Technologies:

Recent advancements in bearing technologies have had a significant impact on idler roller performance. Precision bearings, such as sealed or shielded bearings, offer enhanced protection against contaminants, moisture, and dust. These bearings minimize friction, reduce power consumption, and increase the lifespan of idler rollers. Additionally, advancements in bearing sealing techniques have improved the reliability of idler rollers in harsh operating conditions, such as high temperatures or heavy dust environments.

- 4. Smart and IoT-enabled Idler Rollers:

The integration of smart and Internet of Things (IoT) technologies into idler rollers has opened up new possibilities for data collection, monitoring, and control. Smart idler rollers can be equipped with sensors, wireless connectivity, and embedded electronics to provide real-time data on roller performance, load conditions, and maintenance needs. This data can be transmitted to a central control system for analysis, enabling predictive maintenance, optimizing operational parameters, and improving overall system efficiency.

- 5. Advanced Coating and Surface Treatments:

Innovations in coating and surface treatments have improved the wear resistance and performance of idler rollers. Advanced coatings, such as ceramic or polymer-based coatings, provide superior abrasion resistance, reduce material buildup, and prevent belt slippage. These coatings also enhance the self-cleaning properties of idler rollers, reducing maintenance requirements and improving the efficiency of material handling systems.

- 6. Energy-Efficient Designs:

Recent advancements in idler roller design focus on energy efficiency. These designs aim to minimize the energy consumption of material handling systems by reducing friction, optimizing bearing configurations, and improving roller alignment. Energy-efficient idler rollers contribute to cost savings, lower environmental impact, and compliance with sustainability goals.

In summary, there have been significant innovations and advancements in idler roller technology in recent years. Self-lubricating rollers, composite materials, precision bearing technologies, smart and IoT-enabled capabilities, advanced coatings, and energy-efficient designs are among the notable developments. These advancements improve the performance, reliability, and sustainability of idler rollers, leading to more efficient and cost-effective material handling systems.

In what industries or applications are idler rollers commonly utilized?

Idler rollers are widely utilized in various industries and applications where material handling is a fundamental process. Their versatility and essential functions make them a crucial component in many different sectors. Here are some of the industries and applications where idler rollers are commonly utilized:

- Mining and Quarrying:

In the mining and quarrying industry, idler rollers are extensively used in conveyor systems to transport bulk materials such as coal, ores, gravel, and aggregates. They provide support to the conveyor belts, ensuring efficient and reliable material transport over long distances. Idler rollers are designed to withstand the harsh environments and heavy loads encountered in mining operations, contributing to the overall productivity and profitability of the industry.

- Manufacturing and Production:

In manufacturing and production facilities, idler rollers are commonly used in conveyor systems for the movement of products and components during various stages of the production process. They facilitate the smooth and controlled transportation of materials between workstations, assembly lines, and storage areas. Idler rollers are utilized in industries such as automotive, electronics, food and beverage, pharmaceuticals, and many others, where efficient material handling is essential for streamlined operations.

- Agriculture:

In the agricultural sector, idler rollers find applications in handling crops, feed, and other agricultural products. Conveyor systems equipped with idler rollers are used in grain handling facilities, silos, and agricultural processing plants. They help transport harvested crops, seeds, and animal feed, ensuring gentle handling and preventing damage during the conveying process. Idler rollers with specialized designs may be used to accommodate specific agricultural products, such as those prone to breakage or contamination.

- Ports and Terminals:

Ports and terminals rely heavily on idler rollers to facilitate the movement of bulk cargo, containers, and other materials. Conveyor systems equipped with idler rollers are used in loading and unloading operations, storage facilities, and container terminals. Idler rollers support the conveyor belts that transport goods between ships, trucks, and storage areas, ensuring efficient material flow and logistics operations in busy port environments.

- Warehousing and Distribution:

In the warehousing and distribution industry, idler rollers play a vital role in conveyor systems used for sorting, picking, and transporting goods within warehouses and distribution centers. They support the conveyor belts used in automated sorting systems, package handling, and order fulfillment processes. Idler rollers help maintain the integrity of packages and products, ensuring smooth and accurate material flow, and improving operational efficiency in fast-paced warehousing and distribution operations.

- Construction and Building Materials:

The construction industry utilizes idler rollers in conveyor systems for handling construction materials such as sand, gravel, concrete, and structural components. Idler rollers support the conveyor belts used in material transport at construction sites, concrete plants, and quarries. They ensure the efficient movement of bulk materials, contributing to timely project completion and cost-effective construction processes.

These are just a few examples of the industries and applications where idler rollers are commonly utilized. Their versatility and importance in material handling make them indispensable components in a wide range of sectors, enabling the efficient and reliable movement of materials in various industrial processes.

editor by Dream 2024-05-16

China best Factory Belt Conveyor Accessories Carrier Carbon Steel Tube Flat Return Idler Roller

Product Description

Factory Supply Conveyor System Roller for Belt Conveyor

Zhongjia Heavy Industry conveyor rollers idlers includes both steel and HDPE carry and return rollers, rubber disc impact and return rollers. The rollers and frames are produced to different standards or designs according to your special working condition requirements with innovative and maintenance saving designs. Our rollers are equipped with quality deep ball ZZ C3 bearings for maximum life. Our rollers are suitable for belt widths 400-2000. Larger sizes also available on your special requirements. Our roller service life can be 30,000 to 50,000 hours under normal working condition and maintenance.

Product Parameters

| Basic information | ||

| 1 | Brand | Zhongjia |

| 2 | Roller Diameter | 63.5 to 219mm. |

| 3 | Roller Length | 190 to 3500mm. |

| 4 | Roller Pipe: | Q235 high-precision ERW seam carbon steel pipe with roundness and straightness to ensure well-balanced rotation. |

| 5 | Shaft | Accurate shaft are made of cold-drawn bright round steel, which is superior in corrosion resistance and stiffness.We have strict control over tolerance of shaft dimension and surface quality.The service lifespan can be well secured and proloned. |

| 6 | Bearing: | Ball bearing provided with C3 group of clearance, ZZ shield deep-groove to ensure a nice fit and off-set any expected temperature rise during operation by means of internal clearance OR according to your requirements. |

| 7 | Bearing Brand | SKF,FAG,NSK, LYC,HRB, or according to your requirements. |

| 8 | Seals | Optimum structure with non-contact type, durable, less rotation-resistance and long life-span feautres, particularly for a long-distance and large capacity conveyor for bulk material. It is approved by national authoritative organization that seal is dustproof and waterproof, its performance proved to be satisfactory and has a long way exceeded the GB and JIS standard after our repeated research and development. |

| 9 | Color | Black, green, red, blue, yellow and customized colors are available |

| 10 | Life Time | 30000-50000hours |

| 11 | Production | 800-1000pcs/day. |

| Standard Diameter | Length scope ( mm) | Bearings Type | Idler’s Shell Wall Thickness | |

| mm | Inch | (Min~Max) | ||

| 63.5 | 2 1/2 | 150~3500 | 204 | 3.0mm~3.75mm |

| 76 | 3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 89 | 3 1/3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 102 | 4 | 150~3500 | 3.5mm~4.0mm | |

| 108 | 4 1/4 | 150~3500 | 3.5mm~4.0mm | |

| 114 | 4 1/2 | 150~3500 | 3.5mm~4.5mm | |

| 127 | 5 | 150~3500 | 3.5mm~4.5mm | |

| 133 | 5 1/4 | 150~3500 | 306 | 3.5mm~4.5mm |

| 140 | 5 1/2 | 150~3500 | 306 | 3.5mm~4.5mm |

| 152 | 6 | 150~3500 | 4.0mm~4.5mm | |

| 159 | 6 1/4 | 150~3500 | 4.0mm~4.5mm | |

| 165 | 6 1/2 | 150~3500 | 308 | 4.5mm~6.0mm |

| 177.8 | 7 | 150~3500 | 309 | 4.5mm~6.0mm |

| 190.7 | 7 1/2 | 150~3500 | 309 | 4.5mm~6.0mm |

| 194 | 7 5/8 | 150~3500 | 310 | 4.5mm~6.0mm |

| 219 | 8 5/8 | 150~3500 | 4.5mm~6.0mm | |

FAQ

Q1. Can I have a sample order for conveyor roller

Yes, we welcome sample order to test and check quality.

Q2. What about the lead time?

1) 2–3 days for sample

2) 20–30 days for mass production. If urgent,we have green channel.

Q3. Do you have any MOQ limit for conveyor roller order?

Low MOQ, 1pc for sample checking is available

Q4. Is it OK to print my logo on conveyor roller product?

Yes. Please inform us your logo or design before mass production

Q5. How to guarantee your quality?

We are 1 of the top suppliers of International famous mining company over years. Excellent quality is well accepted.

Please contact us for more details. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Transport Package: | Wooden Case |

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Are there innovations or advancements in idler roller technology that have emerged recently?

Yes, there have been several innovations and advancements in idler roller technology that have emerged recently. These advancements aim to improve the performance, reliability, and sustainability of idler rollers in material handling systems. Here’s a detailed explanation of some of the recent innovations in idler roller technology:

- 1. Self-Lubricating Idler Rollers:

One notable advancement is the development of self-lubricating idler rollers. Traditional idler rollers require regular lubrication to reduce friction and prevent premature wear. However, self-lubricating idler rollers incorporate innovative materials and lubrication mechanisms that eliminate the need for external lubrication. This reduces maintenance requirements, lowers operational costs, and improves overall system efficiency.

- 2. Composite and Lightweight Materials:

Advancements in material science have led to the use of composite and lightweight materials in idler roller construction. These materials offer high strength-to-weight ratios, improved wear resistance, and corrosion resistance. Composite idler rollers are not only durable but also contribute to energy savings by reducing the weight and inertia of the rotating components. The use of lightweight materials also reduces the load on conveyor systems and extends their service life.

- 3. Precision Bearing Technologies:

Recent advancements in bearing technologies have had a significant impact on idler roller performance. Precision bearings, such as sealed or shielded bearings, offer enhanced protection against contaminants, moisture, and dust. These bearings minimize friction, reduce power consumption, and increase the lifespan of idler rollers. Additionally, advancements in bearing sealing techniques have improved the reliability of idler rollers in harsh operating conditions, such as high temperatures or heavy dust environments.

- 4. Smart and IoT-enabled Idler Rollers:

The integration of smart and Internet of Things (IoT) technologies into idler rollers has opened up new possibilities for data collection, monitoring, and control. Smart idler rollers can be equipped with sensors, wireless connectivity, and embedded electronics to provide real-time data on roller performance, load conditions, and maintenance needs. This data can be transmitted to a central control system for analysis, enabling predictive maintenance, optimizing operational parameters, and improving overall system efficiency.

- 5. Advanced Coating and Surface Treatments:

Innovations in coating and surface treatments have improved the wear resistance and performance of idler rollers. Advanced coatings, such as ceramic or polymer-based coatings, provide superior abrasion resistance, reduce material buildup, and prevent belt slippage. These coatings also enhance the self-cleaning properties of idler rollers, reducing maintenance requirements and improving the efficiency of material handling systems.

- 6. Energy-Efficient Designs:

Recent advancements in idler roller design focus on energy efficiency. These designs aim to minimize the energy consumption of material handling systems by reducing friction, optimizing bearing configurations, and improving roller alignment. Energy-efficient idler rollers contribute to cost savings, lower environmental impact, and compliance with sustainability goals.

In summary, there have been significant innovations and advancements in idler roller technology in recent years. Self-lubricating rollers, composite materials, precision bearing technologies, smart and IoT-enabled capabilities, advanced coatings, and energy-efficient designs are among the notable developments. These advancements improve the performance, reliability, and sustainability of idler rollers, leading to more efficient and cost-effective material handling systems.

What are the different types and configurations of idler rollers available in the market?

In the market, there are several types and configurations of idler rollers available, each designed to meet specific requirements and optimize the performance of conveyor systems. Here are some of the different types and configurations of idler rollers commonly found:

- Troughing Idler Rollers:

Troughing idler rollers are one of the most common types of idler rollers used in conveyor systems. They have a concave shape that helps create a trough in the conveyor belt to contain and guide the conveyed material. Troughing idler rollers are typically used in the carrying side of the conveyor belt to provide support and prevent material spillage. They are available in various configurations, including three-roll, five-roll, and six-roll designs, depending on the specific application requirements.

- Impact Idler Rollers:

Impact idler rollers are designed to absorb the impact of heavy or sharp-edged materials during the loading process. They are used in areas where the conveyed material experiences high impact forces, such as loading zones and transfer points. Impact idler rollers are constructed with a reinforced frame and resilient rings or discs to cushion the material’s impact, protecting the conveyor belt from damage and reducing material degradation.

- Return Idler Rollers:

Return idler rollers are used on the return side of the conveyor belt to support the belt and help maintain its tension. They are typically placed in the underside of the conveyor frame and assist in belt tracking and alignment. Return idler rollers are available in various configurations, including flat, v-shaped, and rubber-disc designs. They are designed to minimize belt sagging, reduce spillage, and ensure proper belt tension, contributing to the overall performance and longevity of the conveyor system.

- Training Idler Rollers:

Training idler rollers, also known as self-aligning idler rollers, are used to assist in belt tracking and alignment. They are typically installed on the return side of the conveyor belt and can be adjusted to apply lateral forces to guide the belt back to the center of the conveyor frame. Training idler rollers help prevent belt misalignment, reduce edge damage, and minimize the risk of material spillage. They are particularly useful in applications where the conveyor belt tends to drift or mistrack.

- Combination Idler Rollers:

Combination idler rollers are designed to combine the functions of different types of idler rollers in a single configuration. They are versatile and can be used in various applications where multiple functions are required. For example, a combination idler roller may incorporate troughing, impact, and return functions in a single roller design. This type of idler roller offers convenience and flexibility in conveyor system design and maintenance.

- Spiral Idler Rollers:

Spiral idler rollers have a unique spiral or helical design on their surface. This design helps to improve material movement on inclines or declines and prevents material slippage. Spiral idler rollers are particularly useful in applications where the conveyor system operates at steep angles or when conveying materials that are prone to slipping, such as wet or oily substances.

These are just a few examples of the different types and configurations of idler rollers available in the market. Each type and configuration is designed to fulfill specific functions and cater to different application requirements. Conveyor system designers and operators can choose the most suitable idler roller types and configurations based on factors such as the material being conveyed, the conveyor system layout, load capacity, environmental conditions, and desired performance outcomes.

editor by Dream 2024-05-16

China Best Sales 2.5 mm Thickness High Quality Standard Carbon Steel Material Conveyor Idler Roller

Product Description

Product Parameters

| Standard Diameter | Length Scope(mm) | Bearings Type (min-max) | Shell Wall Thickness | |

| mm | inch | |||

| 63.5 | 2 1/2 | 150-3500 | 6204 | 2.0-3.75mm |

| 76 | 3 | 2.0-4.0mm | ||

| 89 | 3 1/3 | 6204 205 | 2.0-4.0mm | |

| 102 | 4 | 2.5-4.0mm | ||

| 108 | 4 1/4 | 2.5-4.0mm | ||

| 114 | 4 1/2 | 2.5-4.5mm | ||

| 127 | 5 | 2.5-4.5mm | ||

| 133 | 5 1/4 | 306 | 2.5-4.5mm | |

| 140 | 5 1/2 | 306 | 3.5-4.5mm | |

|

TD75 Conveyor |

||

|

Conveyor Belt Width (mm) |

Carrier Roller Size (mm) |

Return Roller Size (mm) |

|

500 |

Φ89*190*220 |

Φ89*600*640 |

|

650 |

Φ89*240*270 |

Φ89*750*790 |

|

800 |

Φ89*305*335 |

Φ89*950*990 |

|

1000 |

Φ108*375*415 |

Φ108*1150*1190 |

|

1200 |

Φ108*455*495 |

Φ108*1400*1440 |

|

1400 |

Φ108*525*565 |

Φ108*1600*1640 |

|

1600 |

Φ133*600*640 |

Φ133*1800*1840 |

|

1800 |

Φ159*670*710 |

Φ159*2000*2040 |

|

2000 |

Φ159*740*780 |

Φ159*2200*2240 |

|

2200 |

Φ194*800*840 |

Φ194*2500*2540 |

FAQ

Q1. Are you a manufacturer or a trading company?

A:We are a professional manufacturer with 30 years of industry experience

Q2. What about the lead time?

A: 2–3 days for sample 15–30 days for mass production.

Q3. What about the Payment?

1)T/T, L/C

2) Western Union, PayPal

3) Alibaba Trade Assurance

Q4. How about package?

1) Inner is packed on round rubber core with 30cm diameter and 12cm x12cm square hole

2) Outer is packed with 1 ply water-proof PP fabric

Q5. Do you have any MOQ limit for conveyor belt order?

A: Low MOQ, 1pc for sample checking is available

Q6. What are the advantages compared with other suppliers?

1) 30+ certificates patents

2) 8 advanced production line

3) 30 years production experience and 15 years export experience

4) Strict management system and complete inspection equipment

Q7. Do you have pre-sale service?

A: Professional engineers provide end-to-end solutions and services for almost any application.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel/ Carbon Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Structure: | Ordinary Roller |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do idler rollers contribute to the adaptability and versatility of conveyor systems in various settings?

Idler rollers play a crucial role in enhancing the adaptability and versatility of conveyor systems in various settings. Here’s a detailed explanation of how idler rollers contribute to the adaptability and versatility:

- 1. Flexibility in Conveyor Design:

Idler rollers provide flexibility in conveyor design by offering different configurations and options. They can be easily integrated into various conveyor layouts, including straight sections, curves, inclines, and declines. Idler rollers come in different sizes, materials, and designs to accommodate specific application requirements. This flexibility allows conveyor systems to be customized and tailored to fit different spatial constraints and production needs, making them adaptable to different settings.

- 2. Handling a Wide Range of Materials:

Idler rollers are designed to handle a wide range of materials, from lightweight and delicate items to heavy and bulky loads. They can be constructed with different surface finishes, such as smooth, grooved, or impact-resistant, to suit specific material characteristics. The ability of idler rollers to handle diverse materials, including packages, containers, bulk materials, and more, makes conveyor systems adaptable to various industries such as manufacturing, logistics, mining, and agriculture.

- 3. Compatibility with Different Conveyor Belt Types:

Idler rollers are compatible with different types of conveyor belts, including fabric belts, modular belts, steel cord belts, and more. They provide support and guidance to the conveyor belt, ensuring proper tracking and alignment. The compatibility with various belt types allows conveyor systems to be adapted for specific application requirements, such as high-speed conveying, heavy-duty operations, or specialized material handling processes.

- 4. Easy Integration with Ancillary Equipment:

Idler rollers can be easily integrated with ancillary equipment and accessories to enhance the functionality and adaptability of conveyor systems. For example, side guide rollers can be added to ensure proper product orientation and prevent lateral movement. Impact idler rollers can be installed in areas where the conveyed material experiences impact or excessive loading. By incorporating such specialized idler rollers and accessories, conveyor systems can be adapted to handle specific product types, optimize material flow, and improve overall system performance.

- 5. Adjustable Configurations and Angles:

Idler rollers offer adjustable configurations and angles, allowing for easy customization and adaptability. Conveyor systems can be designed with adjustable idler frames, allowing the height and angle of the rollers to be modified to accommodate changes in product size, weight, or process requirements. This adjustability enables conveyor systems to adapt to evolving production needs and handle a variety of product dimensions, contributing to their versatility in different settings.

- 6. Modular and Expandable Designs:

Many idler roller systems are designed with modularity and expandability in mind. They consist of individual idler roller units that can be easily connected and disconnected, allowing for flexible system configurations and future expansions. Conveyor systems can be adapted and scaled up or down based on changing production demands, facility layouts, or operational requirements. This modularity and expandability make idler rollers an integral component in creating versatile and adaptable conveyor systems.

In summary, idler rollers contribute significantly to the adaptability and versatility of conveyor systems in various settings. Their flexibility in conveyor design, ability to handle diverse materials, compatibility with different belt types, easy integration with ancillary equipment, adjustable configurations and angles, and modular designs make them essential for creating conveyor systems that can be adapted to different industries, applications, and production needs.

Can you explain the primary purposes and roles of idler rollers in material handling?

Idler rollers play a crucial role in material handling systems, serving several primary purposes and fulfilling essential roles. These rollers are key components that support and guide the conveyor belt or other conveying surfaces, facilitating the efficient movement of materials. Here are the primary purposes and roles of idler rollers in material handling:

- Supporting the Conveyor Belt:

One of the primary purposes of idler rollers is to provide support to the conveyor belt. They create a stable platform for the belt to rest on and distribute the weight of the conveyed materials. Idler rollers are strategically positioned at regular intervals along the conveyor system, forming a series of support points. These support points prevent excessive sagging or deformation of the belt, ensuring smooth and consistent material movement. By supporting the belt, idler rollers help prevent belt damage, reduce spillage, and maintain overall system integrity.

- Guiding the Conveyor Belt:

Idler rollers also play a critical role in guiding the conveyor belt along its intended path. They help maintain proper belt alignment and prevent it from deviating or wandering off track. Idler rollers are designed with precise dimensions and smooth surfaces to ensure the belt’s centered position within the conveyor frame. Proper alignment is essential to prevent material spillage, belt misalignment, and potential damage to the system. By guiding the belt, idler rollers contribute to the overall efficiency and reliability of material handling operations.

- Reducing Friction and Energy Consumption:

Idler rollers help reduce friction between the belt and the supporting structure of the conveyor system. As the belt rolls over the idler rollers, the contact area and frictional resistance are minimized. This reduction in friction results in lower power requirements and energy consumption. By reducing the energy needed to move the belt, idler rollers contribute to the overall efficiency of the material handling system. They help optimize energy usage and reduce operational costs.

- Ensuring Belt Tension:

Idler rollers also play a role in ensuring proper belt tension in material handling systems. They support the return side of the conveyor belt, helping to maintain its tension. By supporting the lower run of the belt, idler rollers prevent excessive sagging and slack, which could lead to belt slippage or disengagement. Proper tensioning is essential for the efficient and reliable operation of the conveyor system. Idler rollers contribute to maintaining the required tension levels, ensuring optimal material handling performance.

- Protecting the Conveyor Belt:

Idler rollers provide a protective function for the conveyor belt and other system components. They help absorb impact and prevent damage caused by heavy or sharp-edged materials falling onto the belt. Impact idler rollers are specifically designed to handle such scenarios and are often positioned in the loading zone. By absorbing the impact forces, these rollers help protect the belt and extend its lifespan. Additionally, idler rollers can contribute to reducing vibration and noise, providing a smoother and quieter material handling environment.

In summary, idler rollers serve critical purposes and play essential roles in material handling systems. They provide support to the conveyor belt, guide it along the correct path, reduce friction and energy consumption, ensure proper belt tension, and protect the belt from damage. By fulfilling these purposes and roles, idler rollers contribute to the overall efficiency, reliability, and longevity of material handling operations.

editor by Dream 2024-05-16

China Standard Cema Offset Center Trough Idler Roller for Quarry

Product Description

ZheJiang CHINAMFG Machinery Manufacturing Co.,LTD. is an innovative manufacturing enterprise specalizing in the production, design, sales and installation of bulk material conveying equipment.

The company mainly provides belt conveyor, tubular belt conveyor, mobile belt conveyor, screw conveyor, Bucket Elevator, chain conveyor, scraper conveyor and other material handling conveying equipment. It also provides conveyor idlers rollers,conveyor drum pulleys,conveyor belts, belt cleaners,impact beds,take-up frame and other components.

Juntong Conveyor has many years of experience in supplying to a diverse range of industries which includes coal, cement,steel iron, chemical,agricultural, power,mining, port, quarrying,mechanical & civil engineering, waste management & recycling.

We have a professional R&D team with plenty technical patents.and we can produce conveyor products in different standards such as CEMA, JIS, ISO, AS, GB and so on. Also,our products have already qualified IS09001, CE, SGS, BV, MA certifications,In addition, CHINAMFG has established friendly and cooperative relationships with ZheJiang Material Handling Research Institute Co.,ltd( BMHRI), CHINAMFG Research Institute (CCRI), HangZhou University of Science and Technology (TYUST) , etc., so that the company’s research and development level has always been at the forefront of innovation in the field of bulk material transportation.CHINAMFG Conveyor has became a CHINAMFG brand with great reputation for providing total conveyor confidence.

| Standard Diameter | Length scope ( mm) | Bearings Type (Min~Max) |

Idler’s Shell Wall Thickness | |

| mm | Inch | |||

| 63.5 | 2 1/2 | 150~3500 | 204 | 3.0mm~3.75mm |

| 76 | 3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 89 | 3 1/3 | 150~3500 | 204 205 | 3.0mm~4.0mm |

| 102 | 4 | 150~3500 | 3.5mm~4.0mm | |

| 108 | 4 1/4 | 150~3500 | 3.5mm~4.0mm | |

| 114 | 4 1/2 | 150~3500 | 3.5mm~4.5mm | |

| 127 | 5 | 150~3500 | 3.5mm~4.5mm | |

| 133 | 5 1/4 | 150~3500 | 306 | 3.5mm~4.5mm |

| 140 | 5 1/2 | 150~3500 | 306 | 3.5mm~4.5mm |

| 152 | 6 | 150~3500 | 4.0mm~4.5mm | |

| 159 | 6 1/4 | 150~3500 | 4.0mm~4.5mm | |

| 165 | 6 1/2 | 150~3500 | 308 | 4.5mm~6.0mm |

| 177.8 | 7 | 150~3500 | 309 | 4.5mm~6.0mm |

| 190.7 | 7 1/2 | 150~3500 | 309 | 4.5mm~6.0mm |

| 194 | 7 5/8 | 150~3500 | 310 | 4.5mm~6.0mm |

| 219 | 8 5/8 | 150~3500 | 4.5mm~6.0mm | |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Steel |

|---|---|

| Application: | Chemical Industry, Grain Transportation, Mining Transport, Power Plant |

| Structure: | Ordinary Roller |

| Bearing Type: | Double Sealed Bearing |

| Type: | Parallel Conveyor Idler |

| Pipe: | Steel(Q235), Stainless Steel(201, 304), Rubber |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Can you provide insights into the importance of proper installation and alignment of idler rollers?

Proper installation and alignment of idler rollers are crucial for the efficient and reliable operation of material handling systems. Here’s a detailed explanation of the importance of proper installation and alignment:

- 1. Belt Tracking and Alignment:

Correct installation and alignment of idler rollers ensure proper tracking and alignment of the conveyor belt. Misaligned or improperly installed idler rollers can cause the belt to deviate from its intended path, resulting in belt mistracking, uneven tension, and potential material spillage. Proper alignment helps maintain consistent belt movement, prevents damage to the belt edges, and minimizes belt wear and tear.

- 2. Reduced Friction and Energy Consumption:

Properly aligned idler rollers minimize friction between the belt and the rollers, reducing energy consumption and optimizing the efficiency of the material handling system. Misalignment or improper installation can lead to increased friction, resulting in higher power requirements and increased wear on the belt and rollers. Proper alignment ensures smooth movement of the belt, reducing energy losses and extending the lifespan of the components.

- 3. Extended Component Life:

Correct installation and alignment contribute to the extended lifespan of idler rollers and other conveyor components. Misalignment or improper installation can cause excessive stress and wear on the rollers, bearings, and other associated components. Over time, this can lead to premature failure, increased maintenance requirements, and higher replacement costs. Proper alignment reduces unnecessary stress and ensures even distribution of forces, prolonging the life of the idler rollers and the overall conveyor system.

- 4. Improved Conveyor Performance:

Properly installed and aligned idler rollers result in improved conveyor performance. When idler rollers are aligned correctly, they provide consistent support to the conveyor belt, maintaining its desired shape and preventing sagging or misshaping. This allows for smooth and efficient material transport, reducing the risk of jams, spillage, or material accumulation. Improved conveyor performance leads to enhanced productivity, reduced downtime, and improved overall material handling efficiency.

- 5. Enhanced Safety:

Proper installation and alignment of idler rollers contribute to a safer working environment. Misaligned or improperly installed idler rollers can create hazardous conditions, such as belt slippage, belt edge damage, or material spillage. These conditions can pose safety risks for workers and increase the likelihood of accidents or injuries. Proper alignment ensures stable and reliable conveyor operation, reducing the potential for safety incidents and creating a safer workplace.

- 6. Cost Savings:

Investing time and effort in proper installation and alignment of idler rollers can result in significant cost savings. Properly aligned idler rollers reduce energy consumption, minimize component wear, and decrease the need for frequent maintenance or repairs. This translates into lower operational costs, increased system uptime, and improved return on investment. Additionally, proper alignment helps avoid costly downtime caused by unexpected failures or belt damage.

In summary, proper installation and alignment of idler rollers are vital for the optimal performance, reliability, and safety of material handling systems. It ensures proper belt tracking, reduces friction and energy consumption, extends component life, improves conveyor performance, enhances safety, and leads to cost savings. Paying attention to the installation and alignment of idler rollers is essential for maximizing the efficiency and longevity of the conveyor system as a whole.

In what industries or applications are idler rollers commonly utilized?

Idler rollers are widely utilized in various industries and applications where material handling is a fundamental process. Their versatility and essential functions make them a crucial component in many different sectors. Here are some of the industries and applications where idler rollers are commonly utilized:

- Mining and Quarrying:

In the mining and quarrying industry, idler rollers are extensively used in conveyor systems to transport bulk materials such as coal, ores, gravel, and aggregates. They provide support to the conveyor belts, ensuring efficient and reliable material transport over long distances. Idler rollers are designed to withstand the harsh environments and heavy loads encountered in mining operations, contributing to the overall productivity and profitability of the industry.

- Manufacturing and Production:

In manufacturing and production facilities, idler rollers are commonly used in conveyor systems for the movement of products and components during various stages of the production process. They facilitate the smooth and controlled transportation of materials between workstations, assembly lines, and storage areas. Idler rollers are utilized in industries such as automotive, electronics, food and beverage, pharmaceuticals, and many others, where efficient material handling is essential for streamlined operations.

- Agriculture:

In the agricultural sector, idler rollers find applications in handling crops, feed, and other agricultural products. Conveyor systems equipped with idler rollers are used in grain handling facilities, silos, and agricultural processing plants. They help transport harvested crops, seeds, and animal feed, ensuring gentle handling and preventing damage during the conveying process. Idler rollers with specialized designs may be used to accommodate specific agricultural products, such as those prone to breakage or contamination.

- Ports and Terminals:

Ports and terminals rely heavily on idler rollers to facilitate the movement of bulk cargo, containers, and other materials. Conveyor systems equipped with idler rollers are used in loading and unloading operations, storage facilities, and container terminals. Idler rollers support the conveyor belts that transport goods between ships, trucks, and storage areas, ensuring efficient material flow and logistics operations in busy port environments.

- Warehousing and Distribution:

In the warehousing and distribution industry, idler rollers play a vital role in conveyor systems used for sorting, picking, and transporting goods within warehouses and distribution centers. They support the conveyor belts used in automated sorting systems, package handling, and order fulfillment processes. Idler rollers help maintain the integrity of packages and products, ensuring smooth and accurate material flow, and improving operational efficiency in fast-paced warehousing and distribution operations.

- Construction and Building Materials:

The construction industry utilizes idler rollers in conveyor systems for handling construction materials such as sand, gravel, concrete, and structural components. Idler rollers support the conveyor belts used in material transport at construction sites, concrete plants, and quarries. They ensure the efficient movement of bulk materials, contributing to timely project completion and cost-effective construction processes.

These are just a few examples of the industries and applications where idler rollers are commonly utilized. Their versatility and importance in material handling make them indispensable components in a wide range of sectors, enabling the efficient and reliable movement of materials in various industrial processes.

editor by Dream 2024-05-15

China wholesaler Plastic Belt Conveyor Idler Roller

Product Description

Plastic belt conveyor idler roller

Introduction